PETRO MANAGEMENT GROUP

- PMG is an oil and gas consulting firm since 1994.

- PMG is one of the best oil and gas consulting company in Calgary, Alberta, as we pride ourselves in offering the best quality work, fast turn around and competitive fees.

- As an upstream oil and gas consulting company, we work with E&P companies to maximize production and improve bottom line results.

- Through our reservoir management studies, we help oil and gas companies to apply optimum development plans and improve the Net Present (PV) of the companies.

- Through our oil and gas consulting and training services we bring significant value to our clients.

PMG has performed numerous fully integrated reservoir engineering studies covering a wide range of oil and reservoirs, both locally and internationally. We have handled studies from a single-well pool waterflood, to large fields with hundreds of wells. Our experienced staff are highly trained to use most of the commercial software including; Eclipse, IMEX, Petrel, and Fekete software.

The reservoir studies performed by PMG include, but not limited to the following:

- Evaluation of primary production performance and the potential for infill drilling

- Conceptual design of E.O.R schemes

- Applications of Multi-Stage Fracturing of Horizontal Wells (MFHW)

- Gas deliverability studies including surface networks

- Unconventional oil and gas optimization studies

- Gas storage

- Sour gas disposal

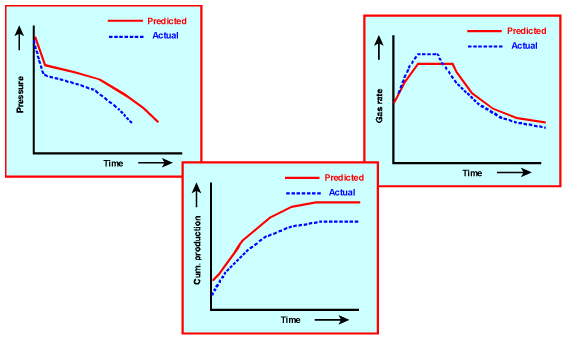

Gas Production Forecasting, including Surface Network

PMG has performed studies to generate realistic production forecasts for a variety of well/field configurations; single/multiple layers, single/multiple pools, using the Piper (Fekete) model. The Piper Software includes the reservoir (tank model) and the surface network. It is expected that this year KAPPA will introduce a new feature of the Rubis Software that can model the reservoir numerically and attach a surface network to it. This will allow the analysis of complex reservoirs and produce reliable surface production forecasts from the wellhead to the inlet of the processing plant.

- Prepare production forecasts for different development scenarios

- Debug bottlenecks of the surface network

- Evaluate benefits of compression

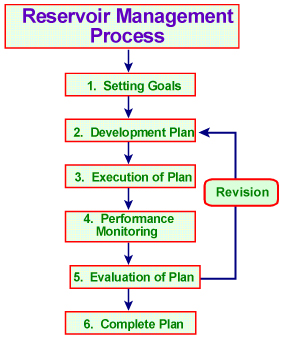

Reservoir Management is the practical science that integrates multi-disciplinary team efforts to predict the performance of various oil and gas reservoirs and prepare optimal development plans and depletion strategy for the full production cycle. To ensure our clients will realize the highest return on investment, we ensure that our recommendations will offer:

- The most cost-effective way to manage the development/management

- The use of new and applicable technologies

- The adherence to the timeline of field development

PMG has added value to many projects by making valuable recommendations to our clients; using the “Reservoir Management” tools, including:

- Infill drilling

- Well stimulation

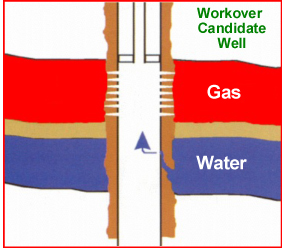

- Well workovers

- Production optimization

- Implementation of secondary and tertiary schemes

- Gas compression and LNG projects

- Meet water disposal/injection requirements by various regulatory agencies.

- Perform the analysis of related well tests such as: injectivity/fall-off tests, step-rate tests, and DFIT

- Prepare projection of long term impact of water disposal

- Advise on water quality and filter size selection

- Offer a training course on water disposal/injection

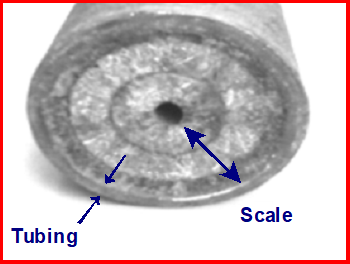

PMG has been involved in numerous pipeline inspection and repair projects in North America and Internationally. PMG utilizes a consortium of some of the most qualified staff (Dr. Adel Guirgis) and the association with several reputable service providers to ensure that the best service and technology are carefully selected and applied for specific pipeline problems. Our services include but not limited to:

- Pipeline Coating Systems – Please Video clip below by Shawcor

- Pipeline Engineering Services

- Leak detection (High-fidelity dynamic sensing (acoustic, temperature, strain) – Please see video clip below by HIfi

- Pressure-Pumping Inspection and Service Repair

- Pipeline Logistics Solutions

- Composite Linepipe

- Corrosion Prevention Services – Please see video clip below by Tuboscope

- Pipeline Inspection Services

- Electrical Wire and Cable

- Non-Destructive Testing Services

- Heat Shrink and Cold-Applied Cable Accessories

- Mechanical Integrity Services

- Tubular Management

Some of the new technologies we use, are as follow:

1. A robot called SEEKUR has a GPS and magnetic detection system that can drive along the pipeline route

1. A robot called SEEKUR has a GPS and magnetic detection system that can drive along the pipeline route

Ground Penetrating Radar can be attached. Two different types of frequencies. This allows for soil condition assessment, any settlement, and also pipeline conditions.

2. A “Drone” can “follow” the SEEKUR robot and has the following sensors:

- The Infrared Thermography (at a proprietary wavelength) that allows for fume and gas detection and any change in soil, vegetation or soil conditions

- A A 4-sensor analyzer that can measure the concentration of C1, CO, LELs and H2S

3. Finally we follow through with another type of “Drone” that has the following sensor:

- A proprietary gas leak detection sensor

- All aircraft and vehicles have the latest and greatest software and hardware

- All aircraft is custom-designed for severe Canadian weather to withstand temperature, wind and adverse weather conditions

4. Fiberoptics monitoring using: Temperature, pressure, chemical leaks, strain, and have a prototype magnetic flux system using fiber data. We supplement by doing simulations and track flow (material balance).

5. Monitoring of oil and gas pipelines by use of VTOL – see attached technical paper.

The systems mentioned above are used by most of the majors in the field including BP Alaska, Japanese gas companies, North American oil and gas companies.

Some of the projects that our consortium was involved in:

1. Rexa Electrohydraulic Project, North America | Connection Systems

2. Occidental Petroleum Pipe Project, Midland, Texas | Composite Production Systems

3. Atlantic Midstream Gathering System Project, Pecos, Texas | Composite Production Systems

4. Papua New Guinea LNG Project, Papua New Guinea | Pipeline Performance

5. Markwest Stack Pipeline Project, Oklahoma | Integrity Management

6. Santos Pipeline Project, South Australia | Composite Production Systems

7. Al-Jalila Field Project, Persian Gulf | Pipeline Performance

8. Pemex Project, Veracruz, Mexico | Composite Production Systems

9. Magellan Midstream Bridgetex Pipeline Project, Permian Basin | Integrity Management

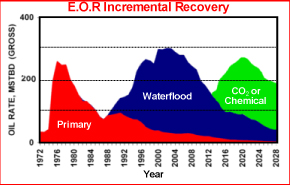

There are many oil fields that have been producing under primary, achieving only a modest ultimate oil recovery. Therefore, there is a massive untapped oil reserve that can only be recovered by applying EOR techniques. PMG has been involved in initiating/designing new EOR schemes and also optimizing existing schemes. Our recommendations have resulted in recognizing upside reserves substantially and increasing project’s NPV.

Services in the area of EOR include:

- Screen for the suitable EOR scheme

- Detailed design of the project

- Define fluid injection requirements

- Select location and define the number of injectors

- Design pilot projects; if deemed essential

- Prepare production forecasts for various field development scenarios

- Run economics to ensure technical and economic benefits are achieved

- Prepare an application to the ERCB to obtain approval

- Optimization of existing projects

The thorough evaluation of field performance by our experienced team resulted in a significant production increase and higher cash flow. Detailed review of drilling, completion, and production history can yield clues to ways to increase production, such as:

- Identification for wellbore/formation damage and making recommendations to stimulate a producer/injector

- Identification of poor completion technique such as inadequate cementing behind the casing

- Diagnosing production problems that could develop along the production history, and preparing remedial action

- Evaluating potential infill drilling

- Implementation of pressure maintenance and EOR schemes

- Installation/optimization of artificial lift methods

- Nodal analysis to optimize wellbore design; tubing size, liquid loading, perforation design, etc.

- Optimization of frac treatment

- Identification of bypassed hydrocarbons from petrophysical analysis

• Setting objectives of the well test

• Selecting the most suitable type of well test

• Design and prepare the related well test program, to ensure conclusive results are obtained.

• Analyze test data using analytical and numerical techniques.

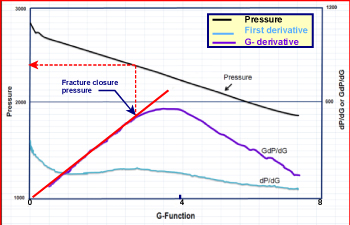

PMG utilizes a combination of the most advanced techniques to analyze well performance, including:

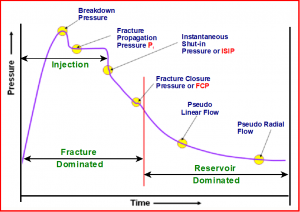

• Pressure Transient Analysis (PTA); using the Saphir software by KAPPA, including Mini Frac (DFIT.

• Rate Transient Analysis (RTA); using Topaze software by KAPPA

At PMG, we developed a unique technique to analyze one of the most complex well tests for Multi-stage Frac Horizontal Wells (MFHW), and multi-well testing using both analytical & numerical techniques.

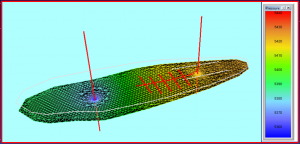

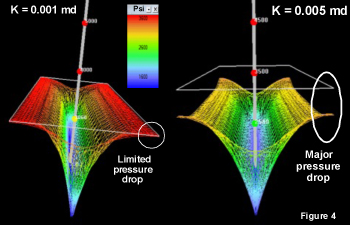

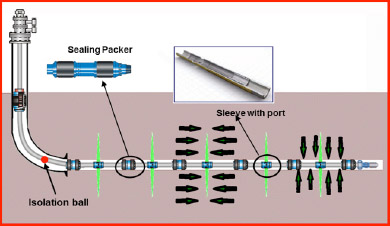

For the first time in the history of the Canadian oil industry, the year 2011 witnessed more horizontal wells being drilled than vertical. This is the result of the rapid advancements in how we drill, complete, and frac Hz wells. Further, many of the challenging reservoirs/formations that the industry is dealing with now, fall in the category of tight, super tight and even ultra tight in the term of the formation permeability. Unconventional reservoirs, such as shale gas, CBM and siltty sandstone, cannot be produced economically without the applications of Multi-Stage Fracing of Horizontal Wells technology.

PMG has taken the lead in helping many oil companies to make important decisions that can reduce development costs and improve project’s NPV. The use of specialized software (Topaze and Rubis) and experienced staff, allowed PMG to assist our clients to optimize the design of MFHW’s, as follows:

- Spacing between the horizontal wells

- The number of frac stages or the spacing between the fracs

- Open hole vs cased hole completion

- Taking advantage of sweet spots present along the Hz well

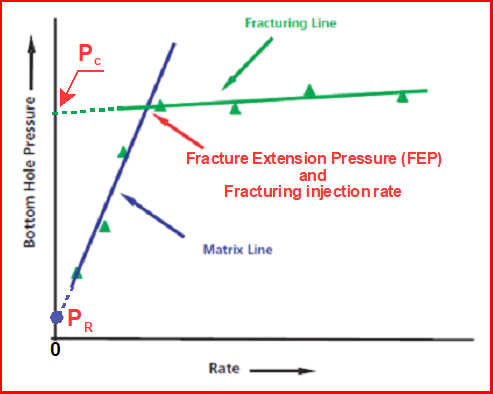

Mini Frac Applications

PMG recommends the use of Mini Frac for the following reasons:

- Obtain important data for frac design

- Obtain other reservoir parameters

- Optimize water/fluid injection in EOR schemes

- Avoid over-injection (over the frac pressure)

- Avoid under-injection (much lower than the frac pressure)

- Determine ceiling injection pressure for steam-flooding projects (ERCB requirement)

- Fracture Propagation Pressure

Instantaneous Shut In Pressure (ISIP)

- Fracture Gradient (ISIP/depth)

- Fracture Closure pressure (FCP)

- Net Pressure

- Identify leakoff mechanism and Coefficient

- Flow regime identification

PMG offers valuable services in the challenging area of engineering including various consulting and training services for CBM, shale gas, and tight sands. Because of the extreme tight nature of these reservoirs, new technology is necessary to endure that commercial production is realized. Our mandate in the area of engineering is to help our clients unlock the potential of Unconventional Reservoirs

- The most cost-effective way to manage the development/management

- Identifying sweet spots; natural fractures and orientation

- Determining formation permeability

- Applications of horizontal well and optimum orientation

- Applying multi-stage fracturing

- Selecting proper well spacing

We have performed a wide range of studies for reservoir producing from the following formations:

- Montney

- Doug

- Shaunovan

- Muskawa (Shale gas – Horn River)

- Barnett shale gas (Fort Worth Basin)

- Viking

- Bakken

- Falher

- Spearfish

- Cardium

- Pekisko

- Glauconite

- Horseshoe Canyon (CBM)

- Mannville (CBM)

Do you need any Oil and Gas Equipment??

PMG has the solution, we offer:

- Advise

- Select the right equipment

- Source the products and solutions

- Offer the most competitive prices

- Deliver in North America and Internationally.

Please see a sample of our products in this equipment catalogue:

Drilling:

- Drilling rigs (top drive)

- Service Rigs

- Service Rigs

Directional Drilling:

- Down hole motors

Pipes:

- Pipelines (all sized)

- Drill Pipes

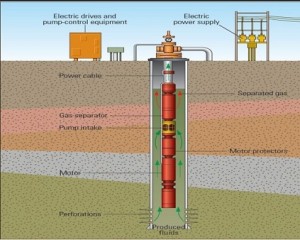

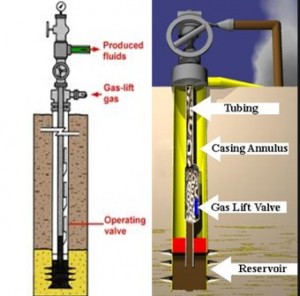

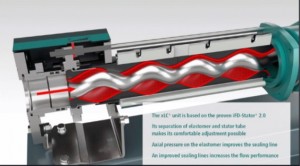

Artificial Lift:

- Electric Submersible Pump (ESP)

- Gas Lift

- Progressive Cavity Pump

- Pump Jack

Single stage radial compressor:

Single-shaft Centrifugal compressor:

- Power Compressor

Pressure Vessels:

- Separators

- Dehydrator

- Treaters

- Heat Exchangers

- Tanks

Plants:

Transportation:

- Crains

- Carriers

Miscellaneous:

- Pneumatic Activator Valves

- Gate Valves

- Xmas Tree

PMG has been helping our clients to prepare necessary applications to the ERCB and other regulatory agencies and ensure approvals are obtained in the most timely manner.

- Downspacing and Holdings

- Commingled Production

- Good Production Practice (GPP)

- Concurrent Production

- Gas-Oil Ratio Penalty Relief

- Enhanced Recovery (Waterflood)

- Water Disposal

- Acid Gas Disposal

- Allowable Calculations and the 0-38 Submissions

Open-hole log analysis, using the Petcom Model, combined with core and geological data, are used to properly characterize the reservoir.

On-site data acquisition, and database preparation for development plans.

Engineering and geological data are used to prepare reserves and economic evaluation for divestiture and acquisition ventures.

Managing the design, installation, commissioning and operation of various telecommunication and SCADA systems in Russia, Egypt, Argentina, Mexico, United States, Canadian Arctic and Canada.