By: Saad Ibrahim, P. Eng (December 3, 2021)

Maximizing water injectivity in water disposal and waterflood projects is essential to the success of these projects. Some techniques are used for this purpose are preventative and others are related to the monitoring of the operation performance.

Preventative measures:

- Water quality recommended standards:

- a) Total suspended solids (TSS) – less than 50 ppm

- b) Total dissolved solids (TDS) compatibility test is required c) Oil contamination (less than 5 ppm recommended)

- d) Bacterial contents (none recommended)

- e) Scale formation – compatibility test is required

- f) Oxygen content – less than 50 pbb depends on the water sourness

- Water filter sizing

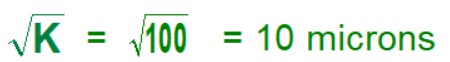

Proper water filter size is the best line of defense to reduce wellbore/formation damage. Laboratory mercury injection test is commonly used to estimate formation average pore size and hence estimate the proper filter size. However, using a “rule of thumb” is fast and cheap for his purpose, as follow:

Pore throat size =

K: is core permeability, md

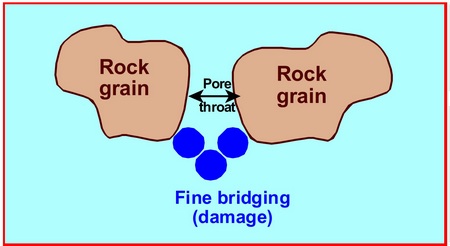

Fine bridging; pore throat plugging typically occurs when a minimum of 3 fines simultaneously pass through. Therefore, to prevent plugging, the filter size should be selected to catch fines of 1/3 of pore throat or larger.

Filter size (above example) = 10/3 = 3 microns

- Well completion:

- Perforating design: Shot density, penetration Depth, Perforating phasing

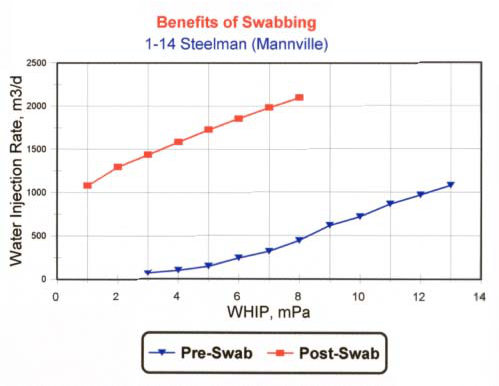

- Well clean up: the graph below shows well injectivity of 300 m3/d without well cleanup prior to injection. Well injectivity increased by 5 folds to 2000 m3/d when well clean up was conducted to prior to injection

Operational techniques:

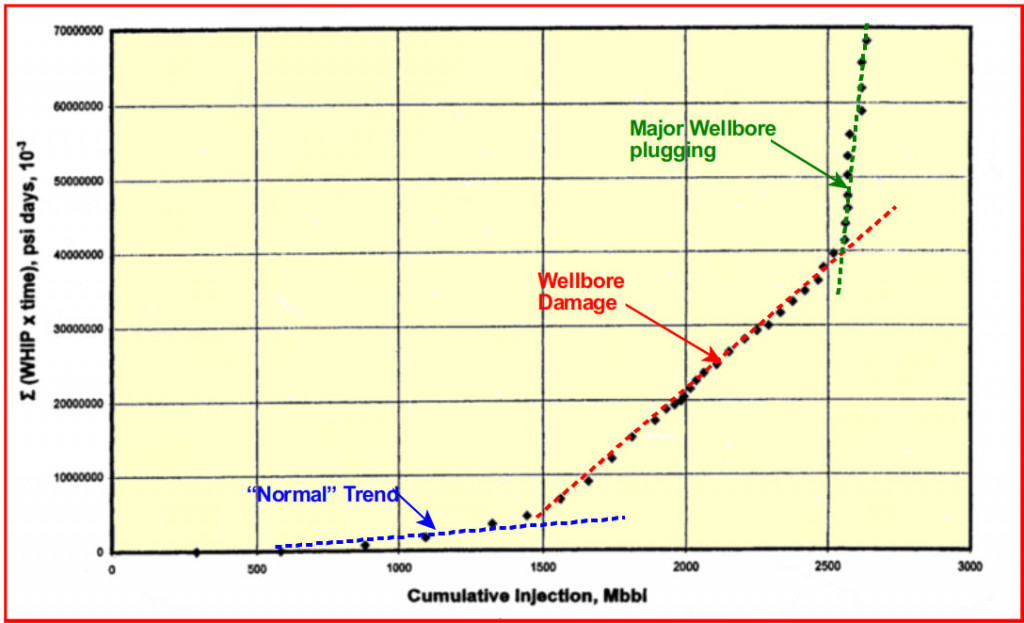

- Hall Plot:

The Hall graph of cumulative water injection volume vs. the WHIP x duration of injection should yield a straight on the linear graph. The curving uptrend indicates that wellbore damage is occurring. The change in slopes of the

linear lines can be used to estimate the increase in the wellbore skin factor

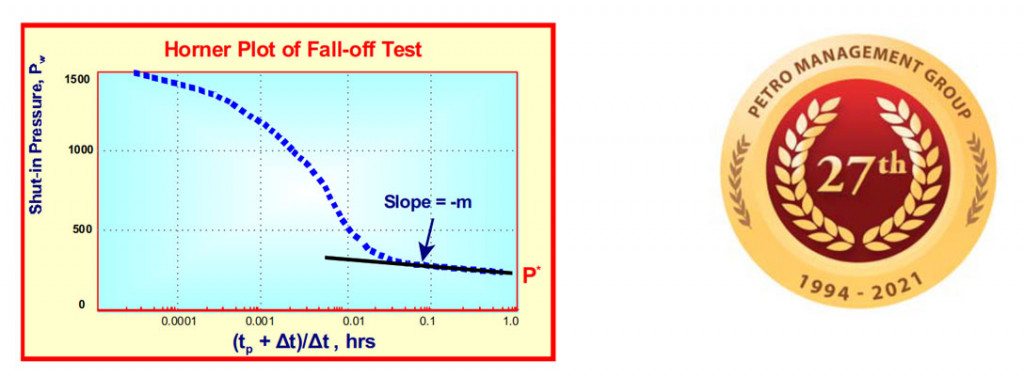

- Well testing (injectivity/fall-off tests) are commonly used to determine the skin factor from the Horner plot to quantify wellbore damage.

For more information related PMG’s consulting and training services:

www.petromgt.com or contact Mr. Saad Ibrahim, P. Eng at (403) 616-8330 e-mail: