Optimum Well Spacing (Abstract from the course “Performance Evaluation of Horizontal Wells) – scheduled April 25-29, 2022)

By: Saad Ibrahim, P. Eng.

Introduction:

The optimum well spacing, especially for tight and unconventional reservoirs is very important, as it will affect the number of wells to achieve the highest technical benefit; Expected Ultimate Recovery (EUR), and also the highest economic benefit; Net Present Value (NPV) of a project. It has been observed in the industry that many operators tend to use a cookie-cutter approach to select well spacing, without performing the proper due diligence.

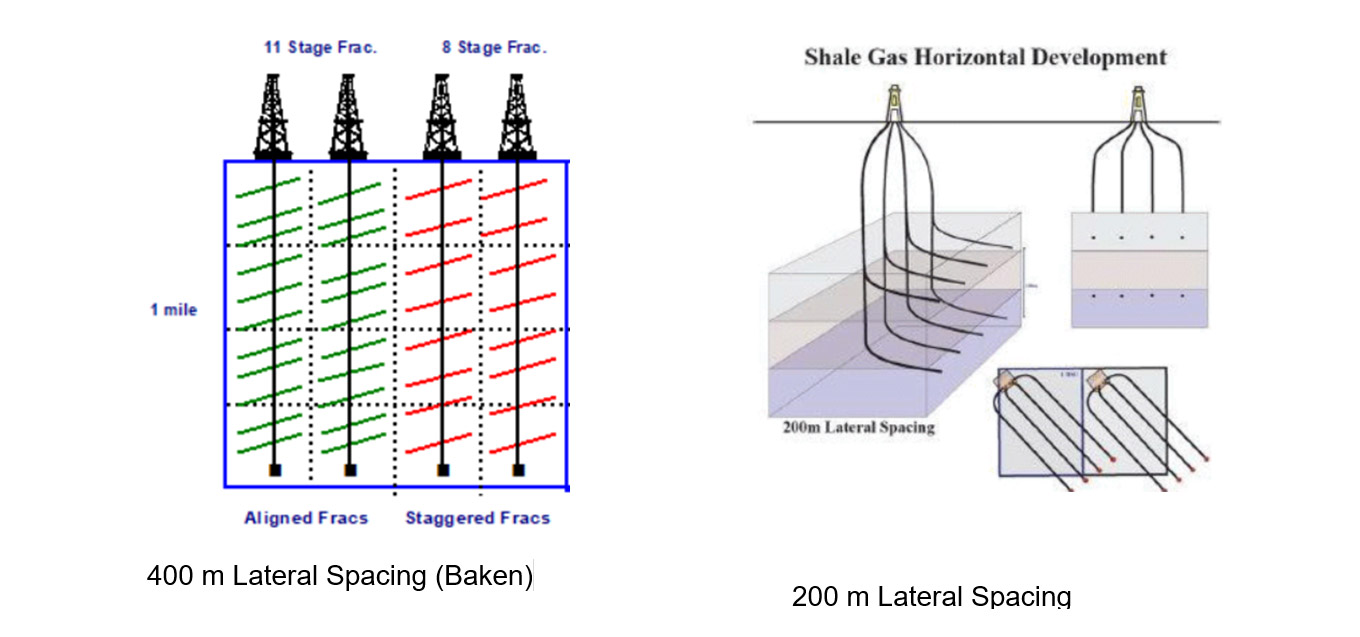

For instance, it has been observed in the Bakken field development, as a rule of thumb, a well spacing of 400 m or 4 wells per section is very common. Further, a small well spacing of 200 m is observed for lower reservoir quality (permeability), such as shale development.

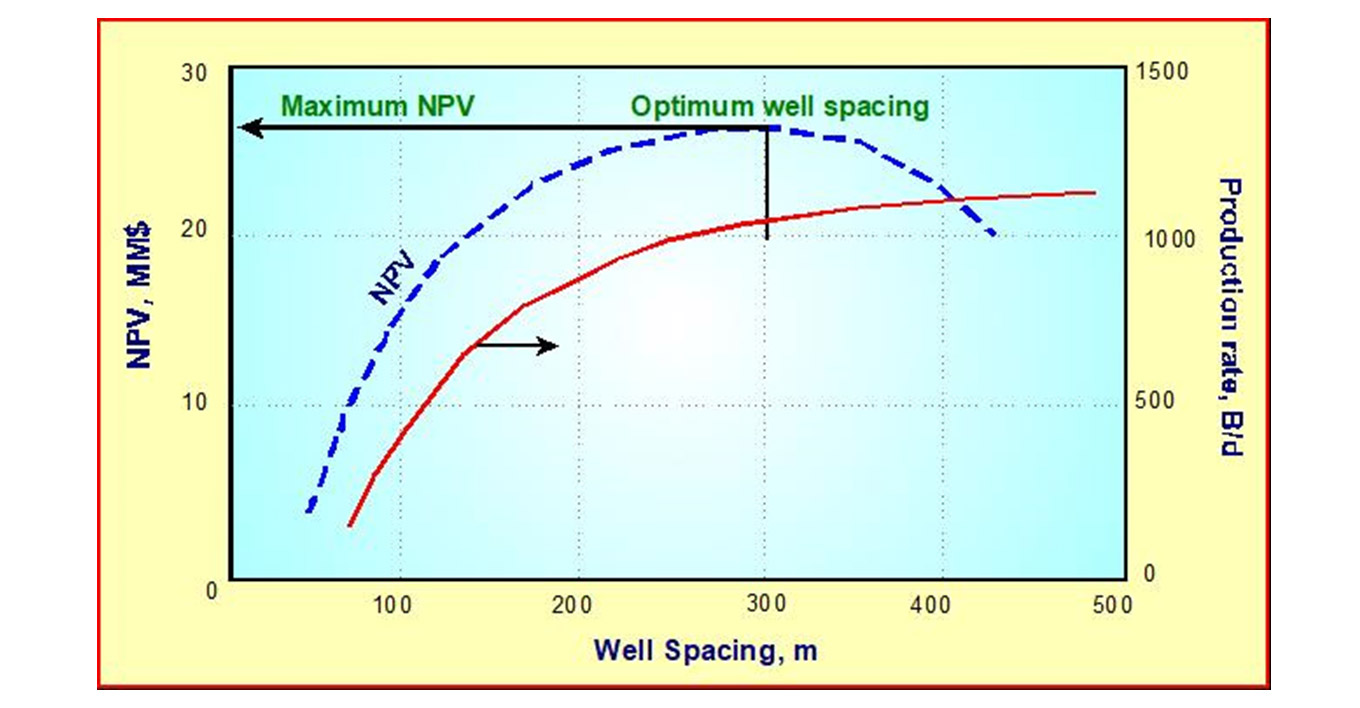

The optimum well spacing should be selected based on both technical and economic evaluation. The reduction of well spacing; meaning drilling more wells, will definitely increase the EUR; however, this may result in a very high cost that will reduce the NPV. Therefore, it is beneficial to determine optimum well spacing by performing both technical and economic evaluations as shown in the graph below.

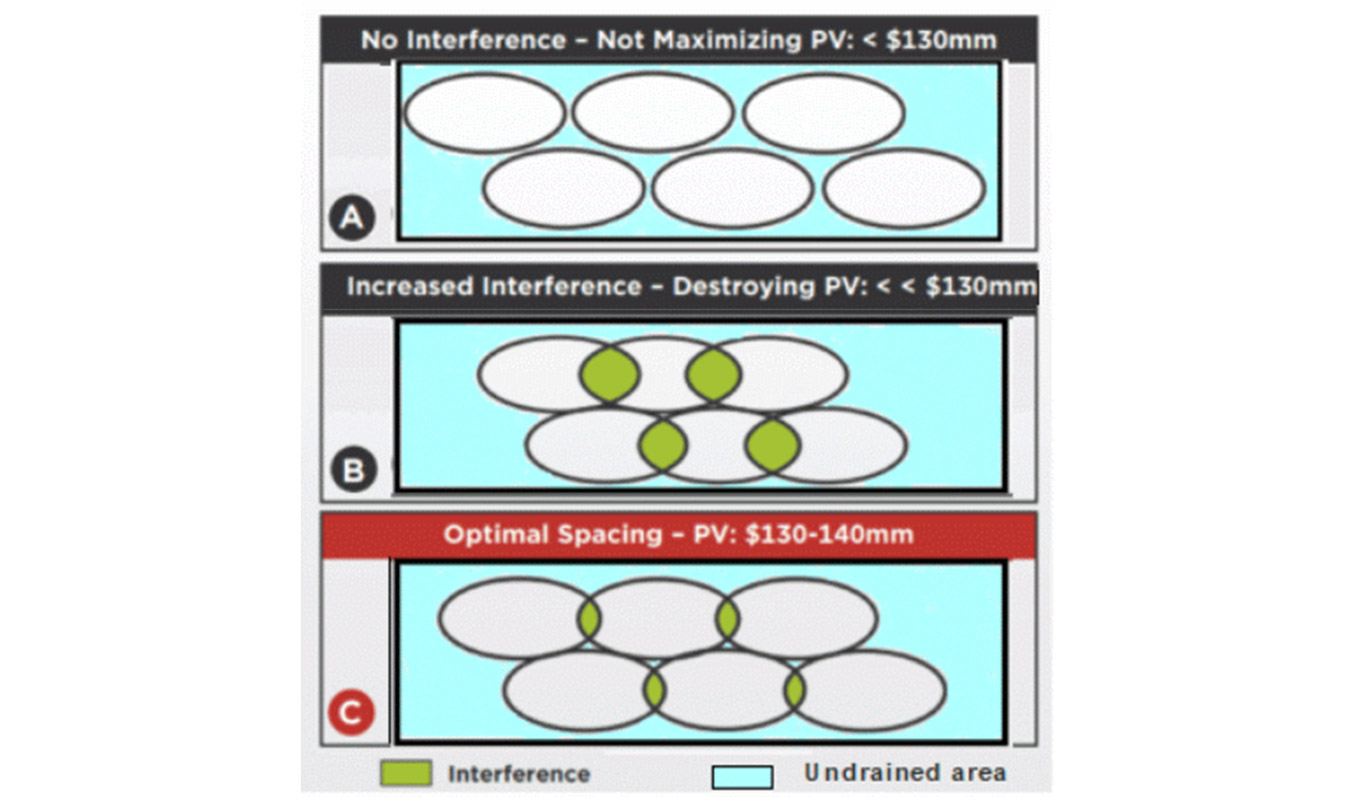

A large well spacing may result in poor recovery mid-way between the wells. Also, tight well spacing may result in well interference and a reduction in the EUR. An interesting study (SPE Argentina, Nov. 2019), has indicated that a slight well interference is beneficial and can result in increasing the EUR. The published graph below, illustrates the benefit of some well interference. The blue areas indicate the undrained portion of the reservoir, as a result of no well inference. Where the green areas, are the portion of the reservoir that encounters well interference.

The evaluation of (Case A), where no well interference is observed, resulted in a NPV less than $MM130. In (case B), where large well inference is observed (green areas), due to small well spacing, resulted in the NVP is much less than $MM 130. The optimum well spacing (Case C), shows a moderate well interference and achieved the highest NPV.

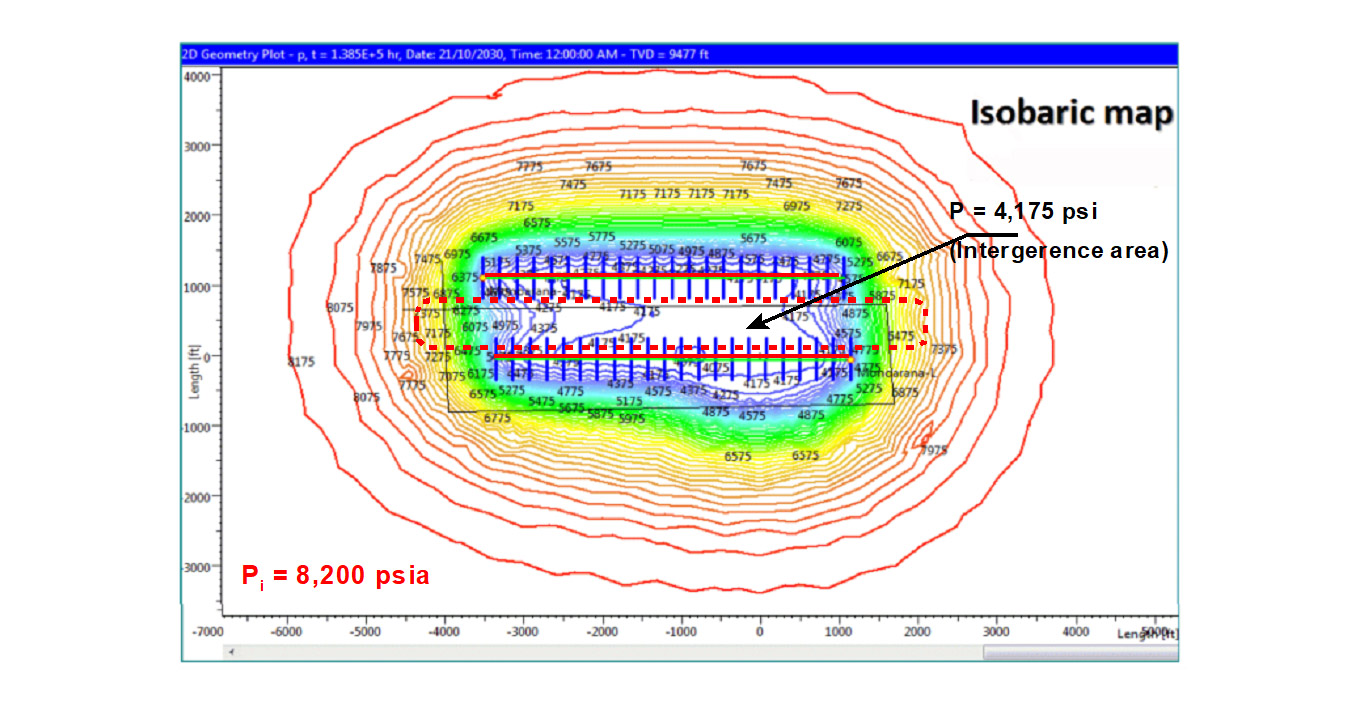

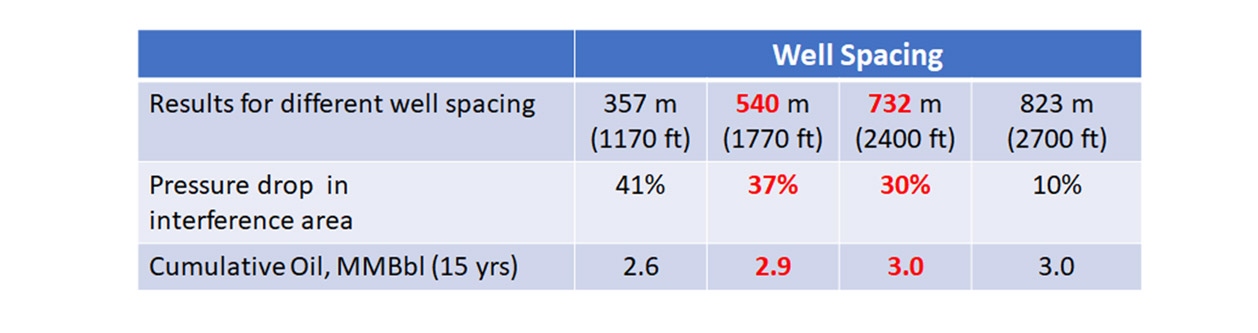

A case study was performed for a reservoir with a low permeability of 0.01 md to evaluate the optimum well spacing, using a numerical model (Kappa/Topaze) by generating the isobaric contour map. Several cases were conducted for a 15 year production period, for a well spacing varying from 357 m to 823 m. The cumulative oil production and the related reservoir pressure depletion in the interference areas are summarized in the table below:

Conclusion:

Conclusion:

- The lowest well spacing of 357 m resulted in a high-pressure drop in the interference area of 41% and the lowest EUR of 2.6 MMBBL

- The largest well spacing of 823 m resulted in the lowest pressure drop in the interference area of only 10% with no increase in EUR of 3.0 MMBBL over a smaller well spacing, indicating a portion of the reservoir has not been depleted.

- The optimum well spacing of 540 m to 732 m resulted in a pressure drop in the interference area between 30% to 37% and a good EUR close to 3.0 MMBBL

- The optimum well spacing should result in a pressure drop in the interference area between 30% and 37% of the initial reservoir pressure

For more information or to register for the course please visit our web: www.petromgt.com, or contact Mr. Saad Ibrahim at saad@petromgt.com or call cell (403) 616-8330